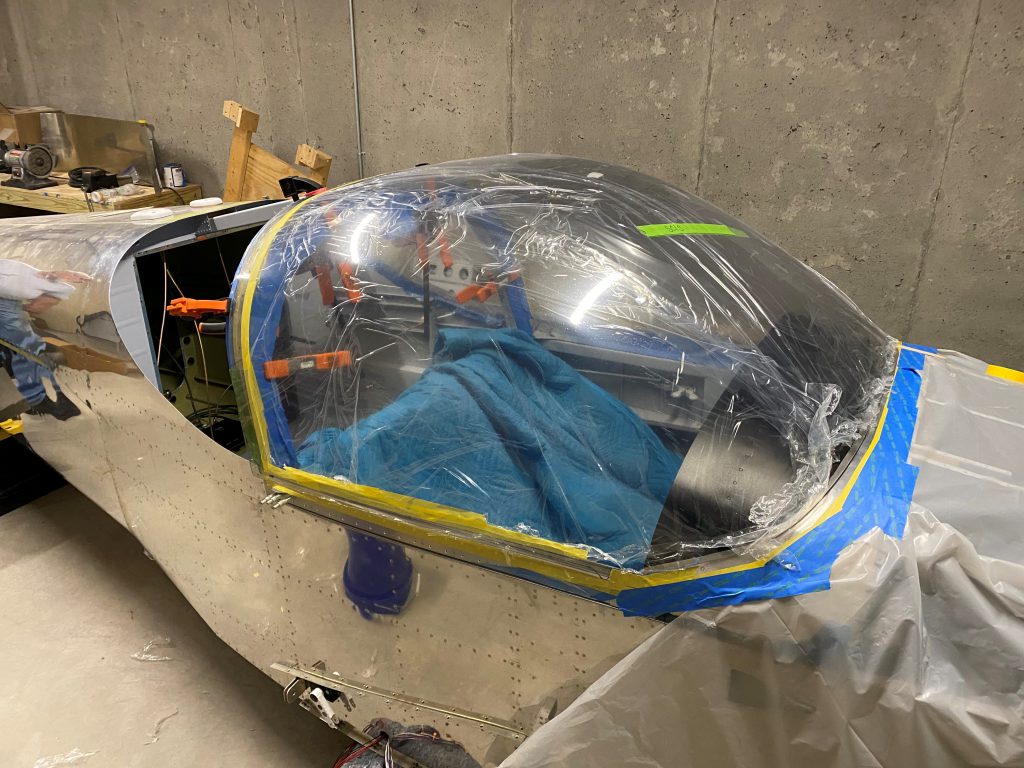

Last night, I got three friends (Chris/Chad/John) to help me move the fuselage out of my basement and up to the garage. Of course it was the hottest, most humid day of the year. It only took about 30 minutes, but we were all drenched in sweat by the time we got it out the window and up to the garage. Only casualty was a cut finger and a scraped leg.

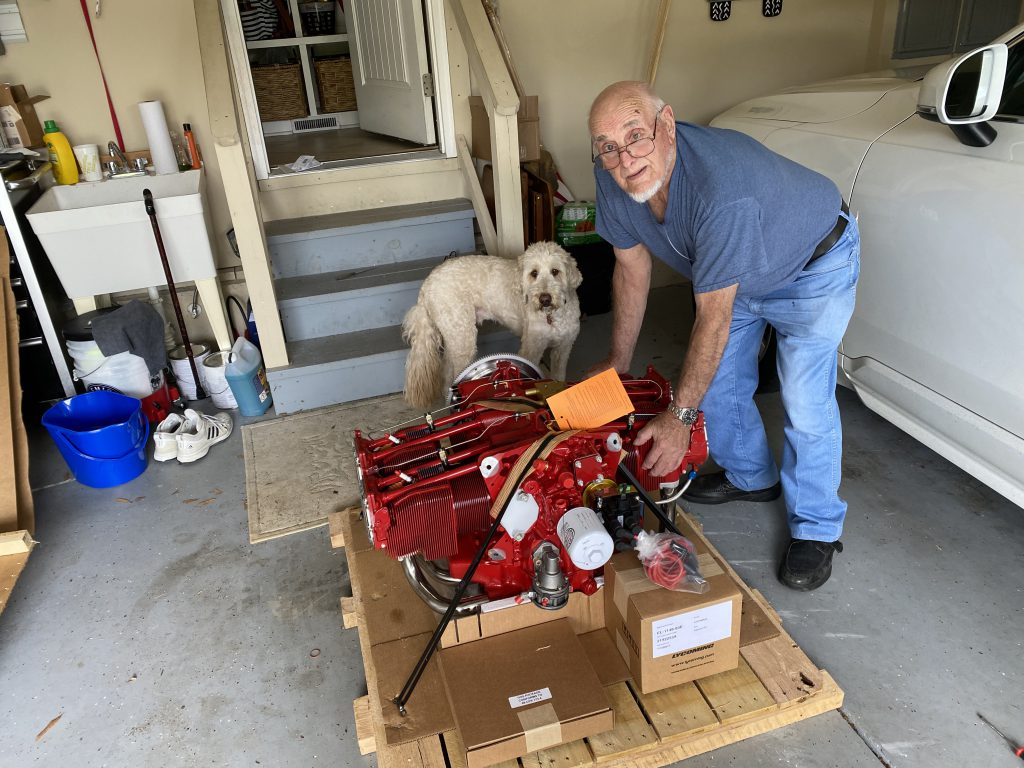

My Dad and I began installing the main landing gear. This looks relatively easy to do, but actually turned out to take a fair amount of effort. There are a lot of bolts to install (26), the tolerances are tight and there is not a lot of room to maneuver hands/wrenches.

It is very important to put the bolts in in the right order. It also helps to have a car jack to lift the gear legs up and wiggle them around to get the bolt / holes to align.

At one point, I thought there was going to be no way to install a washer and nut on several bolts that come out inside the wing spar box. After lots of cussing and complaining (by me) my father noticed that you could reach that area from outside the airplane and then getting these nuts on became trivial. Not bad for an old guy.

There were a couple bolts that were in places that my hands simply don’t fit. I enlisted Marianne to help. Her hands are smaller and she was easily able to install the bolts in a place I would have needed hours (and luck) to install.

Tomorrow, we will install the axles, check alignment and install the wheels, brakes and tires. Then it will be onto the nose gear which looks a bit more complicated.

6 hours (3 hours x 2 people)