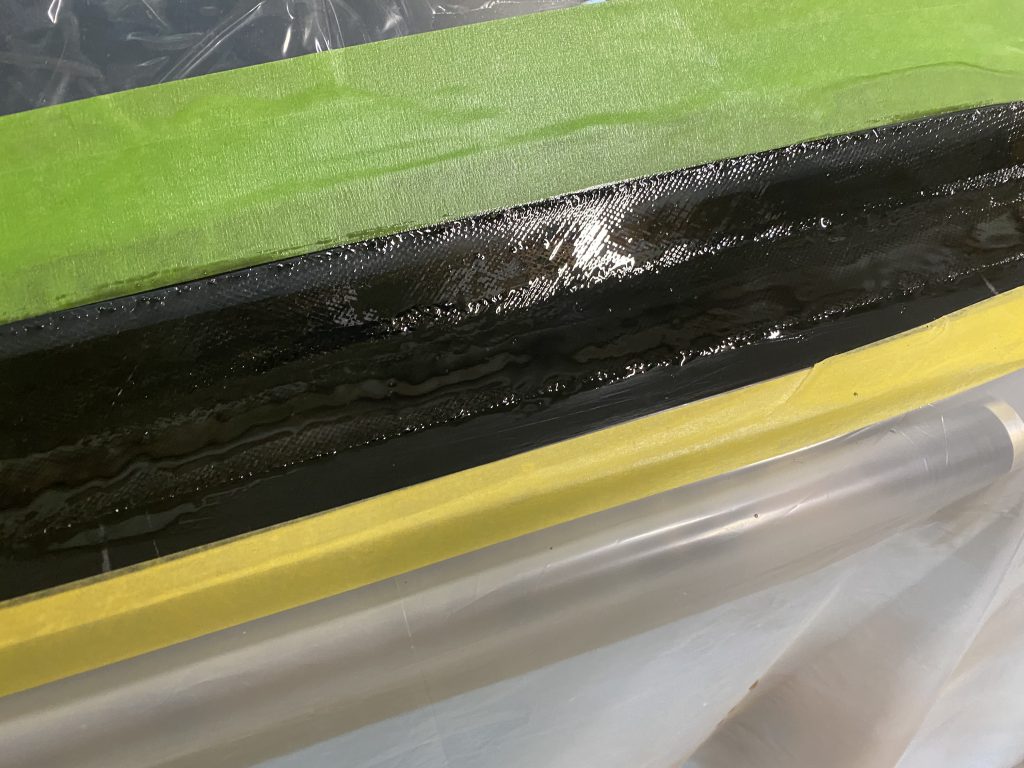

My Dad and I did the fiberglass fairing at the front of the windshield. Not going to win any awards, but overall pretty happy with the way the fiberglass came out. Still lots of sanding and shaping to do.

Note for those new to fiber glass work. The West System pumps can fail to provide the right mixture of resin to hardener. Having too much hardener is better than not enough. The pumps should supply a FULL stroke of fluid for each pump. My resin pump was providing resin for only the second half of the stroke which resulted in too much hardener for a given amount of resin. The lesson here is to occasionally check the mix by weight or volume and not always rely on the pump.

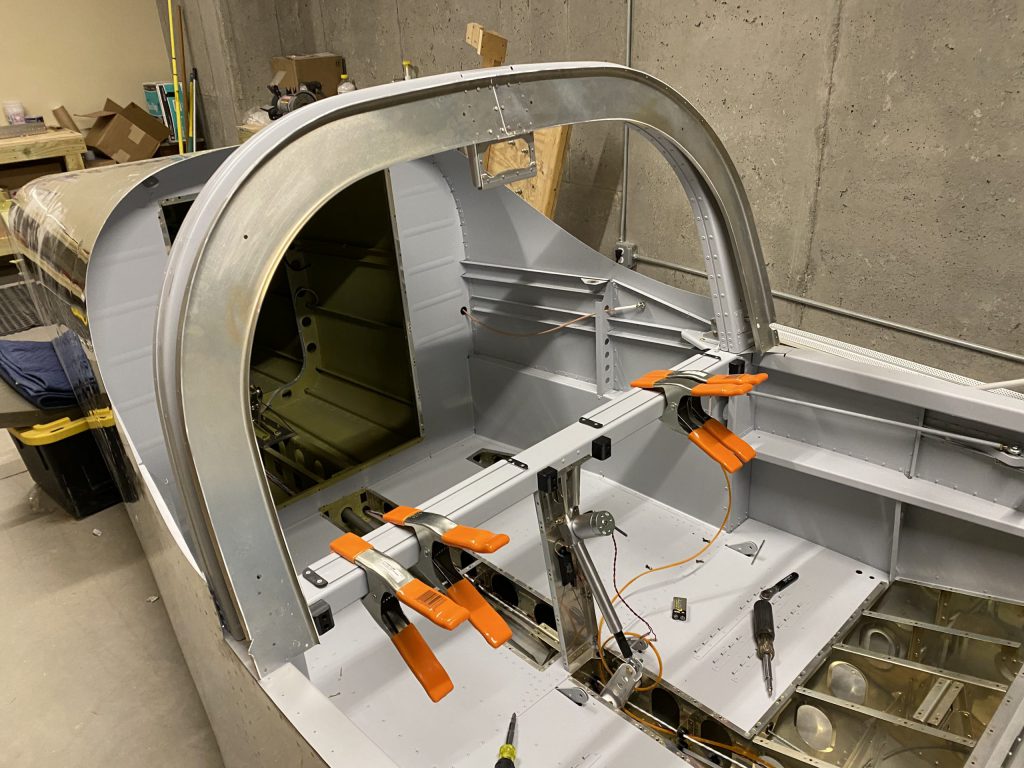

We also worked on the throttle/pitch/mixture/alt air quadrant. This took longer than you might expect. We had to measure and drill the proper holes in the plate (supplied by SteinAir), mount the cables and then mount the plate to the airplane. Then we had to secure the cables and run them through the firewall. The penetration for the firewall is an eyeball grommet by Doubletree (TTP-S). They are $44 per grommet and I am going to re-do one of them because the hole is too big. I also need to install the adel clamps inside the cockpit.

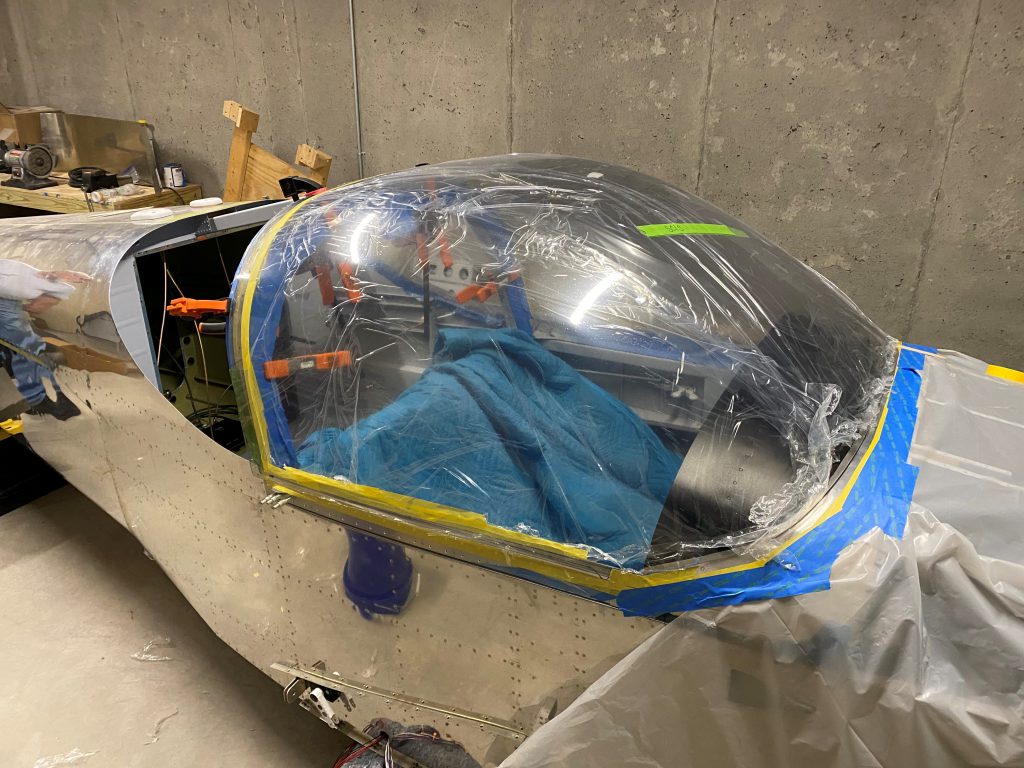

Finally, we did most of the prep work for installing the back window. Similar to the canopy the prep work takes way longer than the actual installation. We will be using Sikaflex to attach the window. I am cautiously hopeful that we will do the install tomorrow evening.

The upcoming schedule is:

Continue miscellaneous tasks like applying firestop caulking to the firewall and installing the fuselage top skin. Late this week we will move the fuselage to the garage so we can begin installing the landing gear and the engine. I am hoping to have this work done in about two weeks so we can move it to the airport near the end of July. Once at the airport we will need to install the propeller, cowling (very time consuming), the wings, tail and the intersection fairings.

I am planning for the DAR inspection around the end of August or the middle of September.

32 hours over several days (2 people).