Jon and I decided to use SikaFlex (glue) to attach the plexi-glass for the canopy and the back window. The process is a bit more difficult than the Van’s method of using screws. We didn’t like creating a stress riser at each of thirty plus holes in the plexi-glass.

The process is :

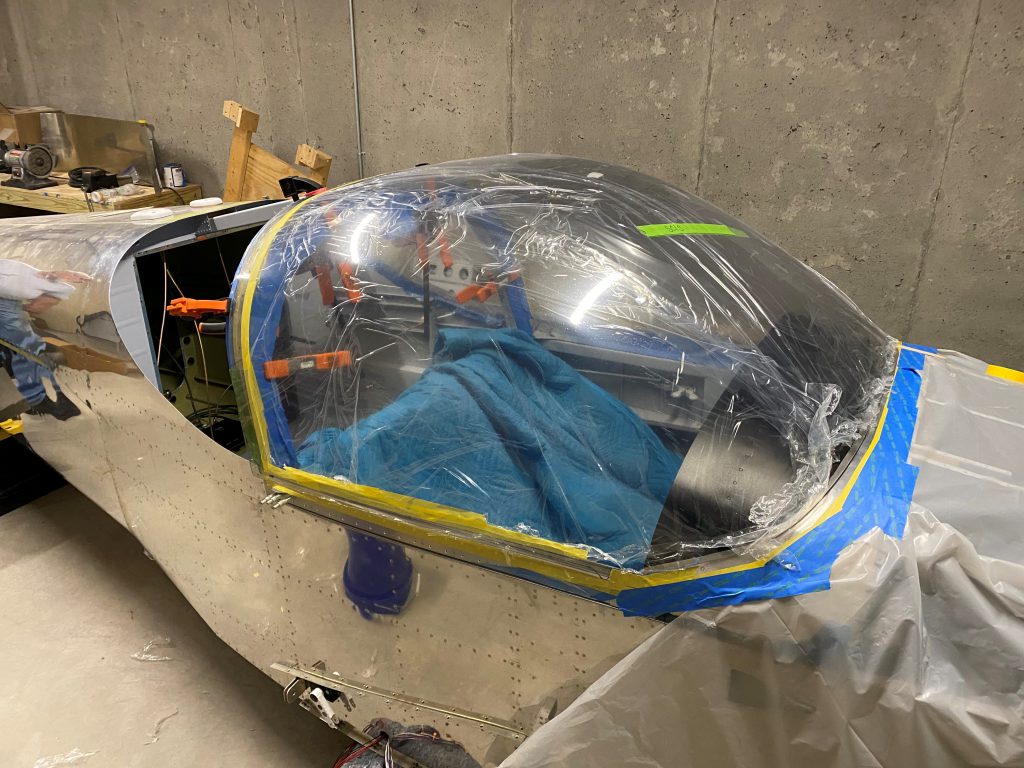

- Mask off everywhere you don’t want the primer to end up.

- Lightly scuff both surfaces (plexi glass with scotchbrite and aluminum with 220 grit sand paper)

- Apply Sikaflex 205 Activator (which seems to be roughly isopropyl alcohol) and let dry 10+ minutes.

- Create stand offs to prevent the plexi-glass from squeezing the glue out. I used tongue depressors for the front and rear and fishing line glued onto the sides.

- Apply Sikaflex 206G+P primer to both the plexi-glass and the airplane body. This stuff is very thin and can easily run. Thus the reason to mask EVERYTHING. It looks like alcohol will remove primer if necessary.

- Apply a bead of Sikaflex 295 UV to the metal surfaces. It is important to cut the tip of the tube properly and to build a small pyramid of glue.

- Lower the canopy onto the frame and weight it down with sandbags. I also installed the side skirts to keep the sides of the plexiglass tightly against the glue.

- Wait 24 hours.

- Remove the tongue depressors and add some additional Sikaflex to fill the holes and make a smooth fillet around the front of the canopy.

- Add the side skirts using the same process (remember to have the wire for the canopy open switch in place).